Manufacturing Process

Precision engineering meets efficient production. See how we build world-class bus seats.

01

Design & Engineering

Our R&D team uses advanced CAD/CAE software to design seats that optimize ergonomics, safety, and weight.

- 3D Modeling

- Finite Element Analysis (FEA)

- Ergonomic Simulation

02

Precision Machining

We utilize CNC machining centers to produce high-precision components with tight tolerances.

- Laser Cutting

- CNC Bending

- Precision Stamping

03

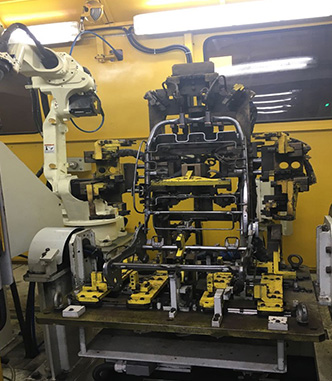

Robotic Welding

Automated robotic welding ensures consistent weld quality and structural integrity for every seat frame.

- MIG/TIG Welding

- Robotic Arms

- Weld Strength Testing

04

Surface Treatment

Advanced coating processes protect frames from corrosion and wear, ensuring long-lasting durability.

- Powder Coating

- Anti-Corrosion Treatment

- Salt Spray Testing

05

Foam & Upholstery

High-resilience molded foam combined with premium fabrics or leather for superior comfort.

- Cold Cure Foam Molding

- Precision Cutting

- Expert Sewing

06

Final Assembly

Skilled technicians assemble all components, followed by rigorous quality inspections.

- Component Assembly

- Functionality Check

- Final QC Inspection